Engine problems…..After a lot of thinking, discussions, backwards and forwards on what to do next, we came to a conclusion – out with the old and in with the new. We just wanted peace of mind and be able to turn the key and the engine starts. Every time! And that meant out with the old engine (again) and in with a new one. Our existing engine is a Perkins 3654H and we believe she was fitted into the boat in 1971. This is not the upright, model and the engine lies on the side with access to most serviceable parts, but not all. The engine was rebuilt in 2019 and even then the engineers struggled to find spare parts for her. In fact, the rebuild involved a repair to two major corroded engine parts (sump and bell housing) as we could not find replacements parts. We were also warned that the oil scavenge pump for the engine was no longer available. There was also a persistent oil leak and we had resigned ourselves to the fact that this was going to be a weekly mop-up job...not ideal. Despite this, we felt (fairly) confident that we would be OK with this engine. Yes, we would be travelling with almost no access to spare parts should there be a problem and we had an oil leak. But it was a risk we were prepared to take as it felt we didn’t have a choice and this was effectively a new engine following a full rebuild.

But now we have a new problem and it involved a lot of white smoke from out of the exhaust and our confidence in the engine shifted. Patrick and the engineers could stab a guess at what it might be but it would take hours and possibly a lot of money to accurately diagnose and fix the problem and this is without addressing the oil leak. A diagnosis was going to involve taking the engine out and possibly sent away (somewhere?) to be diagnosed. The engineers said they could start having a look to get a view of what might be wrong, but it probably beyond their remit. They also repeated their concern/warning about not being able to find spare parts to do any work or parts for us to keep onboard as spares. So they gave us some time to decide what to do next.

What we really wanted was peace of mind. We wanted to be able to turn the key, knowing that she was going to start and we could move on and travel. Particularly in a foreign country. We decided that travelling with an old risky engine with no part numbers and reduced access to spare/replacement parts is not a game we wish to play.

So we dug deep and then deeper into our pockets and we decided to proceed with a new engine. Patrick and the engineers discussed options, considering the space and height restrictions of the engine bay and also what our requirements were. The decision was a Nanni 115, a 4 cyclinder turbo engine. Nanni was an engine Patrick had always had in mind should we have come to this very point. The beauty of this engine, besides being new and fitting in the engine bay, is there are no electronics, its just a simple diesel engine. It was also agreed to fit a thrust bearing, so the new engine will run smoother.

Once we got over the initial shock of the cost of this, we were excited to be moving in this direction. So we “pushed the button” and a new engine and all the extra bits were ordered.

The engineers got ready and they lifted out our very broken engine, which was a sad moment for us as we had tried so hard to keep her going and she had given us some fun adventures.

Once the engine was out we were made aware of two more issues that would have put halt to our trip, and again, before we even really got started. The engineers also showed us how corroded the exhaust manifold heat exchanger was and they estimated we only had a few hours of motoring left on this manifold.

Also, the engine was actually touching the bottom of the hull. We always knew it was a tight fit in the engine bay and Patrick had never been able to even slide oil-absorbing sheets between the engine and the hull. What we were not aware of was that the engine was rubbing away at the hull when running!

Looking back, I suspect our initial response to all of this must have been disbelief, but also a sense of relief and further commitment to a new engine.

So the planning and initial work for the fit of the Nanni began. Patrick spent a few days cleaning up the bilges and getting ready for a brand new engine. The existing bearers for the Perkins were too wide for the narrower Nanni. So new steel bearers were made, painted and fitted to the existing bearers. The fire extinguisher was removed and we are going to have to find a new space for it. It is attached to the front bulkhead and is wide and in the way. The Perkins had the exhaust on the starboard side, it ran up and over the starboard fuel tank and down the starboard side of the boat. The Nanni has the exhaust on the port side. So they are going to have to run the exhaust pipe round the back of the engine to join up with the existing exhaust.

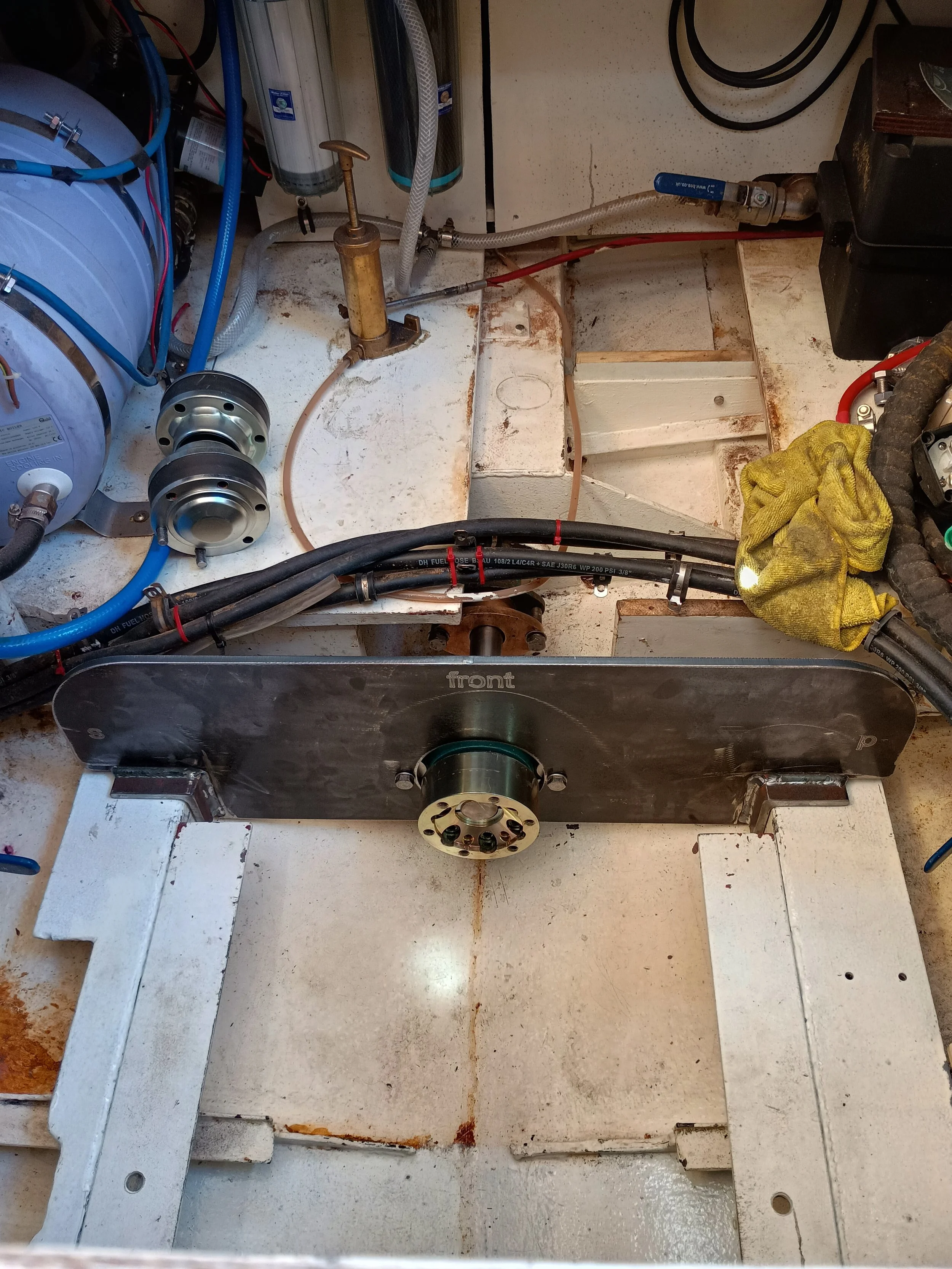

A steel plate was needed for the thrust bearing, so that was measured up and the template sent away to be completed.

Fortunately the generator did not have to be moved, only taken out for the engine fitting but it could go back in the same spot. That would have been another huge job if it needed to be moved elsewhere. We will have to find a new spot for the generator battery though.

Once the new bearers were in, the Nanni was dropped through the roof to check that everything was dimensionally correct. Although the engine wasn't in the boat for long, it was exciting to see it in there, all shiny, new and blue.

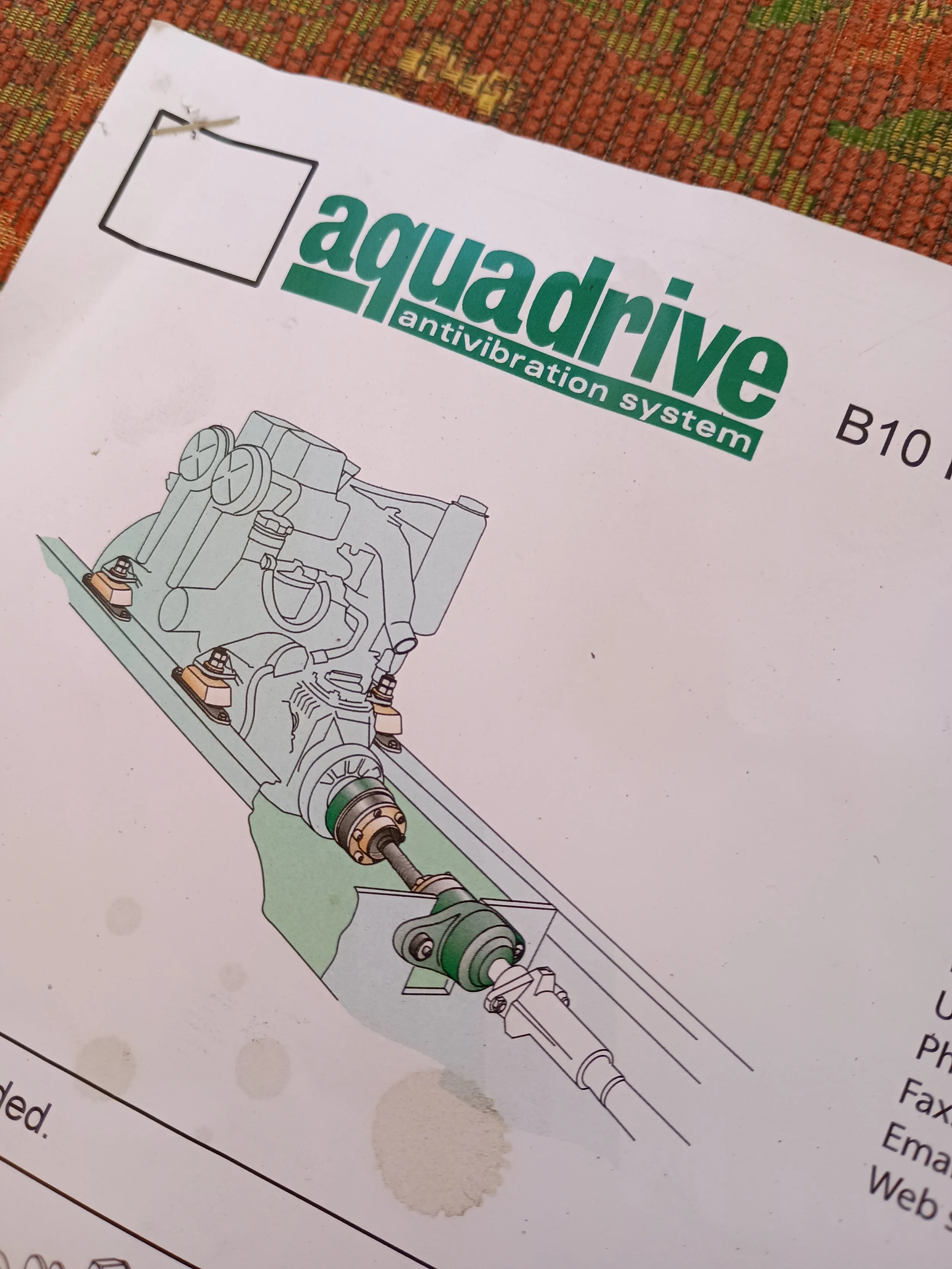

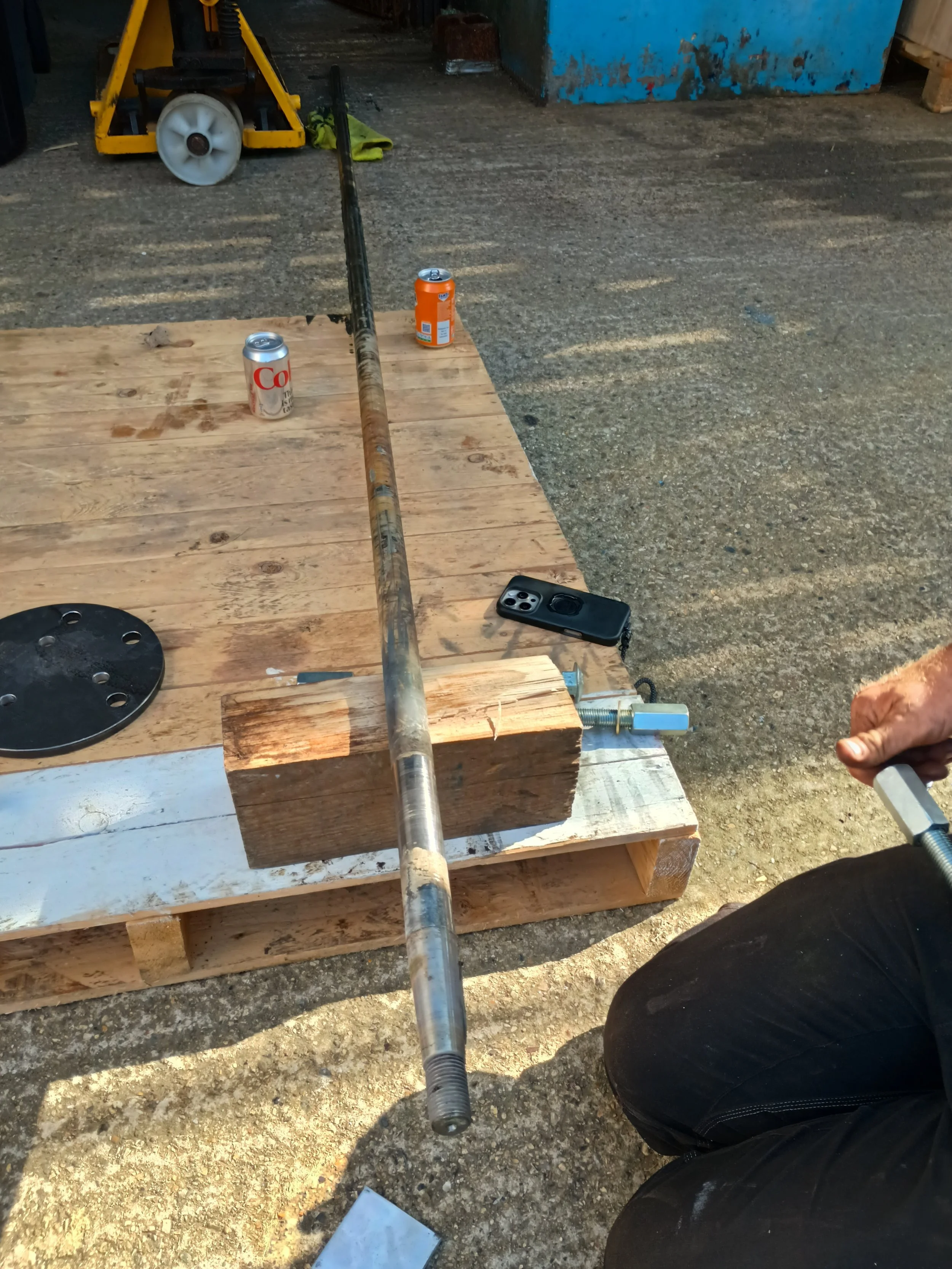

Then she was lifted back out and the engineers got into the engine bay to start the proper fitting work. They first had to remove the shaft coupling that was there from the Perkins, in order to fit the thrust bearing. (At this point we should have KNOWN that we were in the quiet before the storm). Removing the old prop shaft coupling was proving to be almost impossible. After a long long struggle, the engineers finally got it off. It took hours of pulling, using gas heat, pulley plate and eventually an angle grinder. Then the problem exposed itself. The shaft was tapered. This problem was explained to me. The new thrust bearing had to be fitted on a square end of a shaft. It was not designed to clamp onto a tapered shaft. To be fair the engineers did explore a few options to overcome this problem… can the tapered end be cut off, creating a square? Not enough shaft left to reach the engine. Do the manufacturers have an “adaptor” for situations like this? No.

The outcome? A new shaft was to be fitted. This is going to involve lifting the boat out of the water with a crane, removing the old shaft and fitting a new one. They estimated a couple of hours and even discussed doing this shaft replacement while the boat was still in the slings of the crane!! That made sense to me because the boat could go straight back in to the water and they continue with the engine fit. Easypeazy!!

Enquiries were made as to how long for a new shaft to be delivered and also when would a crane be available for the lift. A little over a week!! Just as UK prepared itself for a heat wave and summer was starting to be a real summer. A summer where travelling on the river would be amazing, long warm days, BBQs, walks. I wanted to cry but also knew this was going to be worth it.

Into day 3 of waiting for a lift out, the engineers stopped by to talk about the exhaust. They had a conversation with the manufacturers of Nanni engines, the engine required a new exhaust. The current exhaust wasn’t fit for purpose. Besides being old, the new engine needed a bigger exhaust. (The old exhaust was a 75mm and Nanni needed 104mm). There would also need to be a water lock installed. This device collects cooling water when the engine is stopped, preventing it from flowing back into the engine and causing damage. It also acts as a muffler to reduce exhaust noise. To fit this larger exhaust pipe we were going to have to give access behind lockers, fridge, dishwasher and some of the cupboards, both in the saloon and galley. The exhaust runs behind all of these, down starboard side under the deck.

So the exhaust pipe and water lock were ordered and the beautiful new engine stayed safe in the workshop. Then we received a call to say we needed a new, larger exhaust tailpipe. As the back of the boat is shaped at a curve, we would not be able to buy one off the shelf, so the new one would need to be made to spec. All of this meant that Deux was going to have to be lifted out and placed on supports in the yard and the work would take longer than a few hours in the slings. Possibly a week of work (two to be cautious).

At this point I was ready to say goodbye to summer. I would watch it go by from the back of the boat, 3 meters high, in the boat yard.

And then it finally happened…. The crane arrived, the exhaust pipe, water lock, tailpipe and a lot of other bits all arrived. As well as the heatwave!!

The boat was lifted out and placed on supports in the yard. The engineers fitted pipes to our water outlets, so while we were on the boat, we could use the shower, hand basin and sink as well as the dishwasher. The toilets in the yard were only a quick ladder climb away, so we didn’t have to use the onboard toilet and fill the holding tank. We had access to electric and water so we were not completely hard done by. And the sunsets were really pretty from so high up. I also got really fit with every day climbing up and down the ladder – the hotter it got, the more beer was needed, the more toilet trips were required, the hotter I got = it was easy to see the cycle!

Over the next few days, the engineers got the prop and rudder off, with a lot of huffing and puffing – the summer temperature was really hot by now. The old shaft came out, the new one went in. The exhaust was huge but was fitted and the “destruction” of the lockers and cupboards wasn't too bad. This was not our first rodeo with Deux Poissons. We had lived through many dismantles and refittings so we took that in our stride. We took advantage of the boat being out of the water and did some jobs that were on our to-do list. I gave the galley cupboards a fresh coat of paint. Patrick replaced the salt water anodes with fresh water ones as we are spending all our time on rivers and canals. He did some paint patching on the hull. Same procedure as normal….. Once cleaned and any flaky paint removed, first coat epoxy, then a coat of underwater primer and then a coat of antifouling. Patrick also cleaned and polished the topsides while I varnished everything twice and repainted the cream decks.

The thrust bearing plate was fitted onto the bearers and the thrust bearing put in situ. The crane man was summoned back and Deux was slowly lowered back into the water.

After an hour in the slings and confirmation that all the water remained outside of the boat, the crane man was sent away. As much as I liked him, I didn’t really want to see him again.

Then the engine fitting was scheduled. A few days later the Nanni was lowered through the ceiling and settled into the engine bay. The exhaust fitting proved to be a challenge but once that was completed and all the other vital parts were fitted and connected, the start key was turned. She started first turn and both Patrick and I were amazed at how quiet she was. We could even talk to each other.

The generator still needed to be refitted and connected up, but we could manage without it (for now). We had a working engine! A quiet, reliable one. And the summer heat wave promised to continue for some time. So we agreed to a little test run the next day and then Patrick and I sat and planned a few days upriver. We will need to come back to have the oil checked and replaced and generator re-fitted but we were so pleased to get away for a while!